Sales Inquiry

Forging Ahead: Revolutionizing the Electrical Industry with Superior Materials

Table of Contents:

1. Introduction

1.1 Overview of forging's role in the evolving electrical industry.

2. The Evolution of Forging

2.1 Historical comparison of casting and forging in electrical component manufacturing.

3. Advantages of Forging

3.1 Benefits of forging for electrical applications.

4. Driving Growth in Forging

4.1 Analysis of global market trends and projections.

5. Meeting Emerging Technology Challenges

5.1 IQS's approach to addressing industry advancements.

6. Adapting to Consumer Preferences

6.1 IQS's commitment to sustainability and innovation.

7. Preparing for Electrification Trends

7.1 IQS's role in supporting future electrical industry needs.

8. Conclusion

9. FAQs

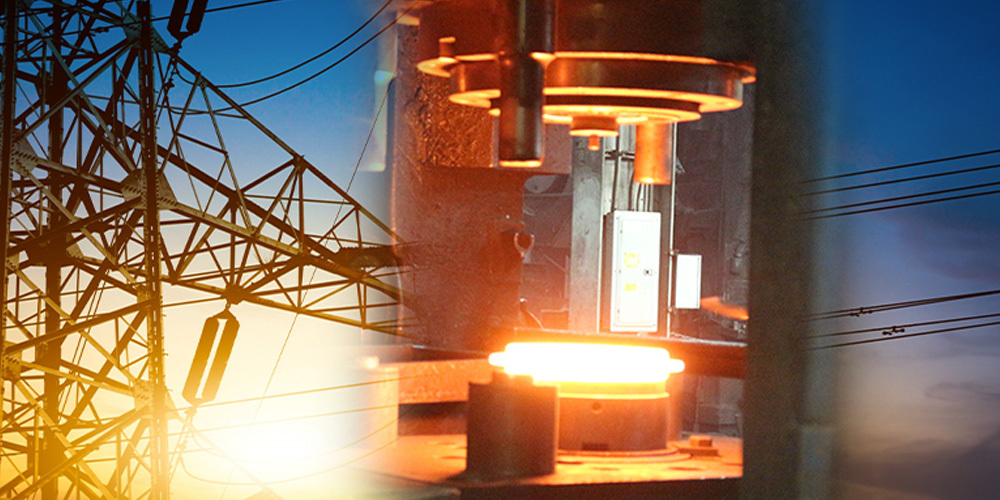

Introduction:

The electrical industry is undergoing a profound transformation, driven by the increasing demand for high-performance materials that can withstand the rigors of modern applications. In this dynamic landscape, forging has emerged as a superior manufacturing method, offering a host of advantages over traditional casting techniques. Let's delve into how the rise of forgings intersects with the changing demands of the electrical industry and explore the pivotal role forging plays in shaping its future, with insights into how IQS Engineering Solutions Pvt. Ltd. is leading the charge in delivering excellence in forging solutions.

The Evolution of Forging in the Electrical Industry:

Historically, casting was the predominant method for creating electrical components. However, as technology advanced and the need for high-performance materials grew, forging emerged as a superior alternative. Unlike casting, which involves pouring molten metal into a mold, forging employs compressive forces to shape metal into precise and intricate forms.

This process results in components with enhanced mechanical properties, superior surface finish, and dimensional accuracy, making them ideal for critical electrical applications. IQS Engineering Solutions Pvt. Ltd., with its expertise in non-ferrous forged components, has been at the forefront of this evolution, providing innovative forging solutions tailored to the unique requirements of the electrical industry.

Advantages of Forging in Electrical Applications:

Forging offers a multitude of benefits that are particularly well-suited to the demands of the electrical industry. IQS's commitment to excellence ensures that its forged components exhibit higher tensile strength, ductility, and toughness compared to cast components, ensuring greater durability and reliability in operation.

Additionally, the forging process yields components with excellent surface finish, reducing the need for additional machining and enhancing overall efficiency. With IQS's focus on dimensional accuracy, customers can be assured of proper fit and function of electrical components in complex systems. Furthermore, forged metal offers enhanced electrical conductivity, providing superior performance in demanding electrical applications.

Driving Growth in the Global Forging Market:

The global forging market has experienced robust growth in recent years, driven by increasing demand for precision engineering and high-performance materials. According to recent reports, the market generated USD 74.1 billion in revenue in 2021 and is projected to continue growing at a CAGR of 4.9%. This growth is fueled by the expanding applications of forgings across various industries, including automotive, aerospace, and electrical.

Meeting the Challenges of Emerging Technologies:

IQS recognizes the importance of skilled professionals in meeting the evolving demands of emerging technologies in the electrical industry. Through investment in training and education programs, IQS ensures that its team remains at the forefront of technological advancements, delivering tailored solutions that meet the unique requirements of its customers.

Adapting to Changing Consumer Preferences:

As consumer preferences shift towards energy efficiency and sustainability, IQS remains committed to developing innovative products and solutions that minimize energy consumption and environmental impact. By leveraging its expertise in forging technology, IQS helps customers meet the growing demand for energy-efficient electrical components, driving sustainability and long-term value.

Preparing for the Future of Electrification:

The power sector is gearing up for accelerating electricity demand driven by electrification trends in transportation, industry, and infrastructure. As electric grids evolve to accommodate this growing demand, new planning tools and strategies will be essential to ensure reliability, efficiency, and sustainability. Forging, with its superior properties and versatility, is poised to play a crucial role in supporting the electrification of various sectors and driving innovation in the electrical industry.

Conclusion:

In conclusion, forging, with its unmatched mechanical properties, excellent surface finish, and dimensional accuracy, stands poised to revolutionize the electrical industry. As a leader in forging solutions, IQS Engineering Solutions Pvt. Ltd. is driving this transformation, delivering excellence and innovation in every component it produces. With a steadfast commitment to quality and customer satisfaction, IQS is shaping the future of the electrical industry and setting new standards of excellence in forging technology.

FAQs:

Q: What makes forging a superior manufacturing method for electrical components?

A: Forging involves shaping metal through compressive forces, resulting in components with enhanced mechanical properties, superior surface finish, and dimensional accuracy compared to casting. These qualities make forged components ideal for critical electrical applications where reliability and performance are paramount.

Q: How does IQS Engineering Solutions Pvt. Ltd. contribute to the evolution of forging in the electrical industry?

A: IQS specializes in non-ferrous forged components and provides innovative forging solutions tailored to the unique requirements of the electrical industry. With a focus on excellence and cutting-edge technology, IQS plays a pivotal role in driving the adoption of forging in electrical applications.

Q: What are the benefits of forging in terms of mechanical properties and surface finish for electrical components?

A: Forged components exhibit higher tensile strength, ductility, and toughness compared to cast components, ensuring greater durability and reliability in operation. Additionally, forging yields components with excellent surface finish, reducing the need for additional machining and enhancing overall efficiency.

Q: How does forging contribute to energy efficiency and sustainability in the electrical industry?

A: By providing energy-efficient electrical components with enhanced mechanical properties, forging helps meet the growing demand for sustainability in the electrical industry. With its superior properties and versatility, forging supports efforts to minimize energy consumption and environmental impact.

Q: How does IQS Engineering Solutions Pvt. Ltd. prepare for the future of electrification in the electrical industry?

A: IQS invests in training and education programs to ensure its team remains at the forefront of technological advancements in the electrical industry. By staying ahead of emerging trends and innovations, IQS delivers tailored solutions that meet the evolving needs of its customers in an electrifying future.