Sales Inquiry

Brass Casting

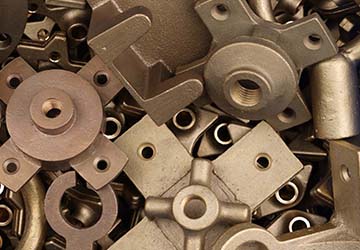

Brass Casting Process

Brass is a generic name that encompasses alloys made from copper and zinc. Brass casting involves using these metal alloys to form metal parts efficiently. Green sand casting is one of the most reliable brass casting methods. This technique involves forming a single-use mold from a sand aggregate and pouring molten brass into that mold. The process works well thanks to green sand's ability to withstand extremely high temperatures. We manufacture and supply wide variety of Brass castings in various sizes and grades up to 10 kg single piece.We also use metal moulds to produce brass castings.

Exploit the following unique characteristics:

- High Strength

- High Performance

- Enhanced Flexibility

- wear-resistance

- Good electrical conductivity

- Excellent Surface Finish

- Resistance to corrosion and rust