Sales Inquiry

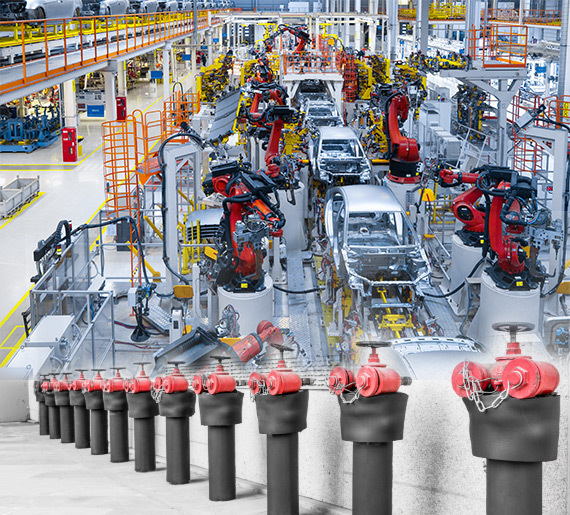

Why do we need Castings and Forgings in the Automotive and Fire & Safety Industries?

Why do we need Castings and Forgings?

Castings are made from a solid block of metal or other material that has been heated to its melting point. The molten metal is poured into a mould cavity until it cools into the desired shape. This process creates an article which can be used for many different purposes such as tooling parts or structural components such as bridges or beams etc. The process also allows continuous production without having to take apart each part after every use (which would require more time).

The resulting product is stronger than the original material and has a higher density. It's also more ductile and has better impact resistance than castings or other types of finished products. This makes them ideal for industrial applications where strength, hardness and toughness are required.

Benefits of Castings and Forgings

These benefits of casted and forged products in the finished products are as follows:

1. Lightweight

2. Durability

3. Long life

4. Strength

The castings and forgings have a variety of applications and can be used for various purposes.

Forgings are produced by heating a piece of metal until it becomes malleable, then shaping it into a desired form. The process can be done with or without the use of tools. Castings are made by pouring molten metal into a mold that has been created using a casting machine.

Brief History of Castings and Forgings

Despite the fact that modern techniques may be relatively new in the context of human civilization, the first metal castings date all the way back to roughly 4000 BC. Due to its malleability, gold was the first metal to be cast during that era, and due to the difficulties in obtaining pure ore, metal from tools and decorations was reused. The oldest known casting, however, is a copper frog, which is said to have been created in Mesopotamia about 3200 BC (present-day Iraq). Due to its stiffness compared to gold, bronze later emerged as the preferred metal for casting. Using permanent stone moulds, bronze was melted and cast into a variety of tools and weapons. By 2800 BC, casting had reached Egypt, and the efficient execution of this procedure had a significant impact on their rise to prominence during the Bronze Age. Around 1300 BC, the Shang Dynasty in China were the first to adopt sand casting while melting metals. The Zhou Dynasty later introduced cast iron to the world approximately 500 BC, but it was primarily utilised by farmers. It took the Qin Dynasty, about 300 years later, for cast iron to be used as a weapon or decorative item.

The automotive, fire and safety industries demand castings and forgings.

These castings and forgings are used to manufacture engines, transmissions and other parts. They are also used in pump manufacturing where they can be made from different materials such as stainless steel or aluminum alloys.

The company IQS Solutions Pvt. Ltd has been in operation since the 2000s. They offer a variety of casting and forging items including aluminium, brass, copper and bronze forgings and also aluminium and brass castings.

They have a wide range of castings and forgings that can be used in the manufacturing of various parts for different industries. They offer products such as bearings, bushings, engine blocks and cylinders which are used in automotive applications.

They also offer products such as manifolds, crankshafts, camshafts and other engine parts. They have a wide range of castings and forgings for construction industries including pumps, valves and fittings.

They have a wide range of products for fire safety applications including sprinkler heads, nozzles and fittings. They also offer products such as washers and gaskets that can be used in various industrial applications.

Conclusion

IQS Engineering Solutions Pvt. Ltd. is a top producer and exporter of Non-Ferrous Forged Components and is a Startup India, MSME India, and MCA Registered Company. We are one of the forging and casting businesses in India that is expanding the quickest. The company works with a variety of product categories, including brass forgings, aluminium forgings, copper forgings, bronze forgings, aluminium castings, and brass castings. Our mission is to distinguish ourselves as the top service providers for non-ferrous casting and forging components both in India and beyond.

Thus, we at IQS Engineering Solutions can cater all your needs.